Product Center

retail price

Market price

weight

kg

inventory

Hidden domain element occupancy

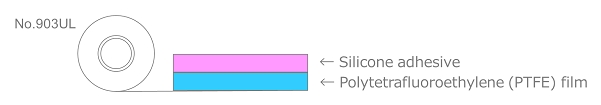

One side silicone gel coated with fluorine plastic film. The tape with silicone resin adhesive can be applied to a fluoroplastic (PTFE) film. It can be used in the temperature range of - 60 ° C to 200 ° C which conforms to the ul-510 flame retardant standard. Excellent electrical insulation and sliding. It can be used in various applications requiring the characteristics of fluorine plastic.

Category:

High Temperature Resistant Material

Characteristic:

Excellent characteristics such as heat resistance, electrical insulation, sliding, waterproofing, and adhesive elimination.

Can be used for a wide temperature range of -60 ° C to 200 ° C (recommended value), and can be used for higher temperatures for a short period of time.

Obtained UL510 flame retardant standard certification (registration number E34833).

It has excellent adhesion to various materials.

Structure:

Specifications:

|

Product Code |

Colour |

Thickness [mm] |

Width [mm] |

Length [m] |

|

No.903UL |

- |

0.08 |

5 - 450 |

10 |

Characteristic:

|

Project |

Company |

Characteristic value |

|||

|---|---|---|---|---|---|

|

Total thickness |

mm |

0.08 |

0.13 |

0.18 |

0.23 |

|

180 ° peel strength |

N/19 mm |

5.6 |

7.1 |

7.4 |

8.7 |

|

Unfolding force |

N/19 mm |

4.4 |

5.8 |

7.1 |

8.9 |

|

Tensile strength |

N/19 mm |

55 |

93 |

160 |

210 |

|

Extension rate |

% |

180 |

220 |

220 |

220 |

|

Breakdown voltage |

kV |

8 |

11 |

14 |

15 |

|

Dynamic Friction Coefficient |

- |

0.1 |

|||

|

Flame Resistance |

- |

UL510 flame retardant (E34833) |

|||

|

Colour |

- |

brown gray |

|||

|

Available temperature |

℃ |

-60 至 200 |

|||

*This data represents an example of measured values, rather than guaranteed achievable values.

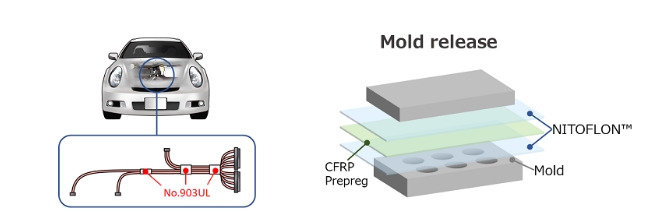

Application:

1. Insulate wires, cables, and coils.

2. Electrode insulation in backup batteries and other energy storage devices.

3. The paper feeding part of the printer is heat-resistant and slides.

4. Insulation and sliding performance of motor drive system.

5. Welding mask.

6. Friction noise control inside the car, or friction control of sliding parts.

7. Improve the viscosity elimination characteristics during the molding process.