Product Center

retail price

Market price

weight

kg

inventory

Hidden domain element occupancy

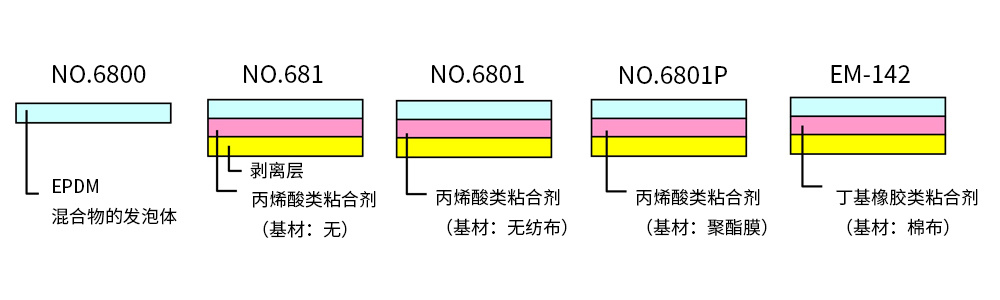

Rich, soft, wrought, independent foam foam, weatherproof, waterproof porous foam sealing material. This is a high performance, foam resistant EPDM mixture with high performance foam foam. NO.6800 The combination of the series and the demand for customers, and the combination of the combination and the combination of the binding and the binding of the bentonite acid are used.

Category:

Buffer material

Characteristic:

1. Good weather resistance and water tightness, with stronger heat resistance than foam waterproofing materials such as polyurethane or polyethylene

EM-142 uses butyl rubber adhesive, which has strong adhesion to rough surfaces

3. No.681, No.6801, and No.6801P use acrylic adhesive, which has excellent retention, heat resistance, and weather resistance. 4. Independent bubble type, with good flexibility and elasticity

5. Even for complex shaped gaps, it can be easily constructed

Construction:

Matters needing attention:

1. Please thoroughly clean the oil, water, and dust on the surface of the object being touched.

When cutting and processing NITTOEPTSEALER using acrylic adhesive (substrate: non-woven fabric), please process it parallel to the length direction. Please note that if processed in the width direction, there may be stretching and shrinking during use.

When cutting NITTOEPTSEALER using butyl rubber adhesive, please process parallel to the length or width direction. Please note that there may be expansion and contraction during use after tilting processing.

4. The adhesive layer is pressure-sensitive, please fully press it when pasting.

The temperature of the pasting operation environment is suitable to be above 10 ℃. In winter, when the temperature is below 10 ℃, the initial adhesive strength decreases

6. Please store the rolled products horizontally to prevent deformation.

7. Please avoid storing in a dark place that is hot, humid, and not directly exposed to sunlight.

Standard size:

|

Thickness (mm) |

Width (mm) |

Length (m) |

|

3~15 |

1000 |

2 |

Characteristic:

According to JIS K 6767

|

Product Name |

Appearance density |

Tensile strength |

Extension |

Compression hardness (N/cm2) |

|

|

25% |

50% |

||||

|

NO.6800 |

0.12 |

35 |

240 |

2.5 |

8.0 |

※The above data is only an example of measured values and is not a guaranteed value.

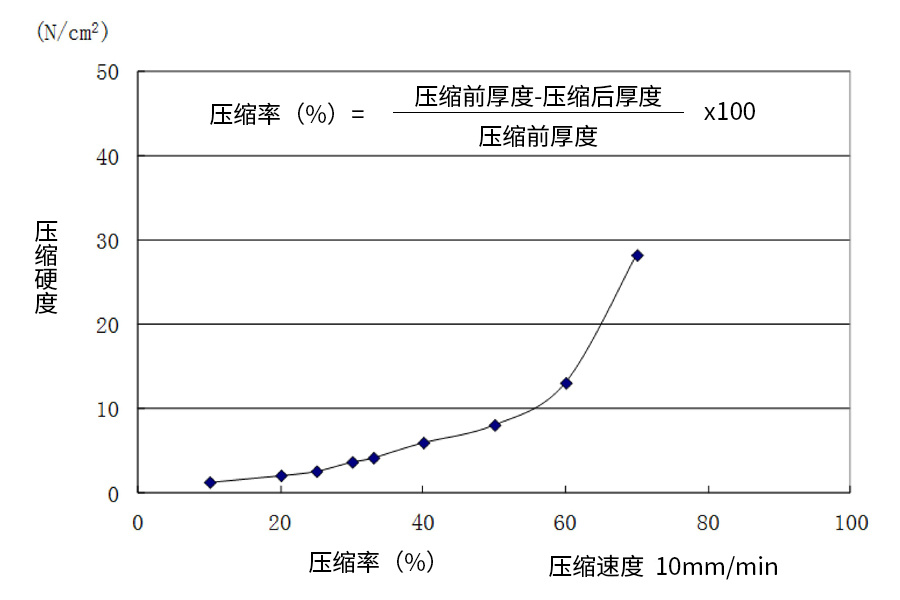

・The relationship between compression ratio and compression hardness of foam

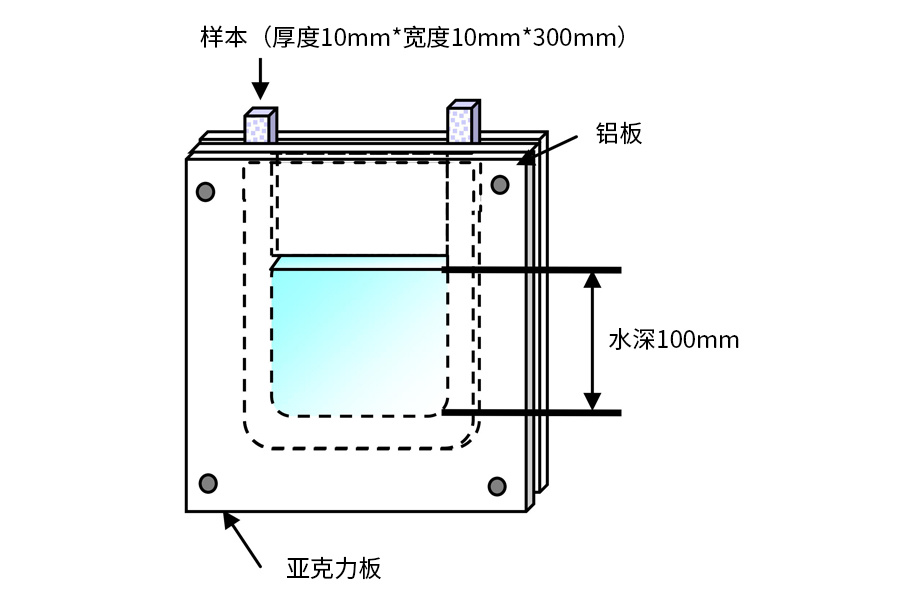

・The relationship between compression rate and water tightness of foam

|

Compression ratio (%) |

NO.6800 |

|

0 |

× |

|

10 |

△ |

|

25 |

○ |

|

50 |

○ |

○:After 30 minutes without any water leakage

△:Water leakage within 30 minutes

×:Within 10 points, there is water leakage

Test method

Clamp each sample with a 10mm wide drilling plate,

Compress and fix according to the specified thickness.

Add water to a depth of 100mm and confirm if there is any leakage.

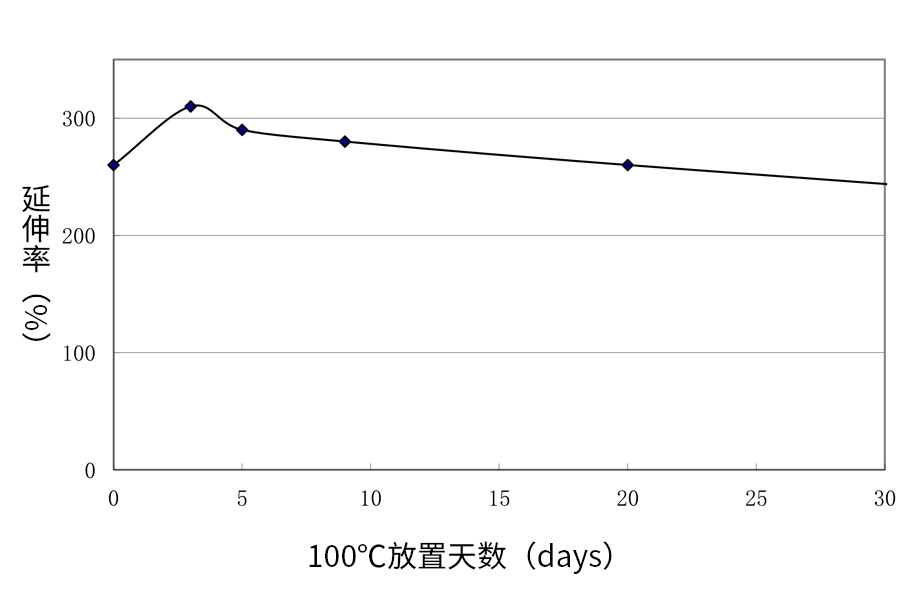

●Heat resistance (change in elongation of foam after being placed in an environment of 100 ℃)

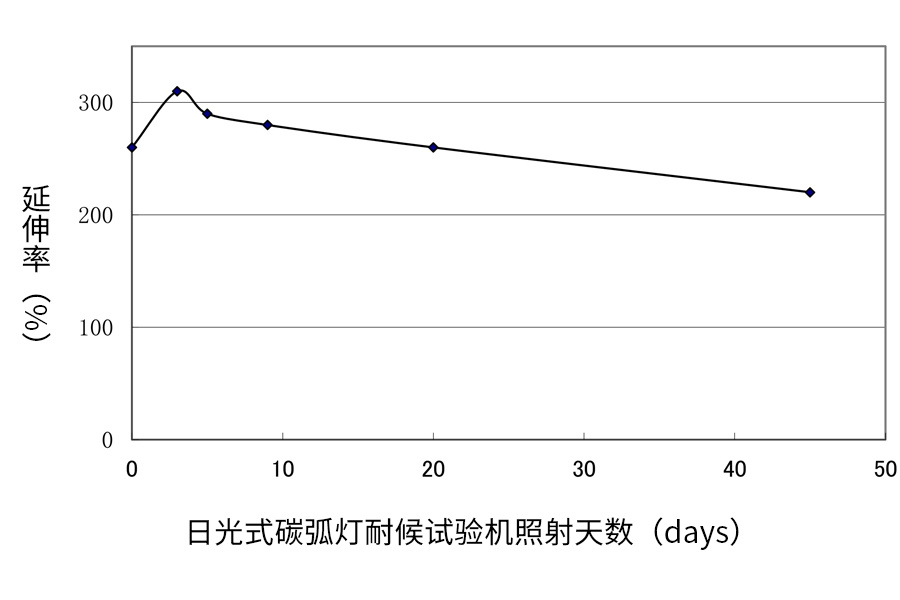

●Weather resistance (change in elongation of foam after UV aging)

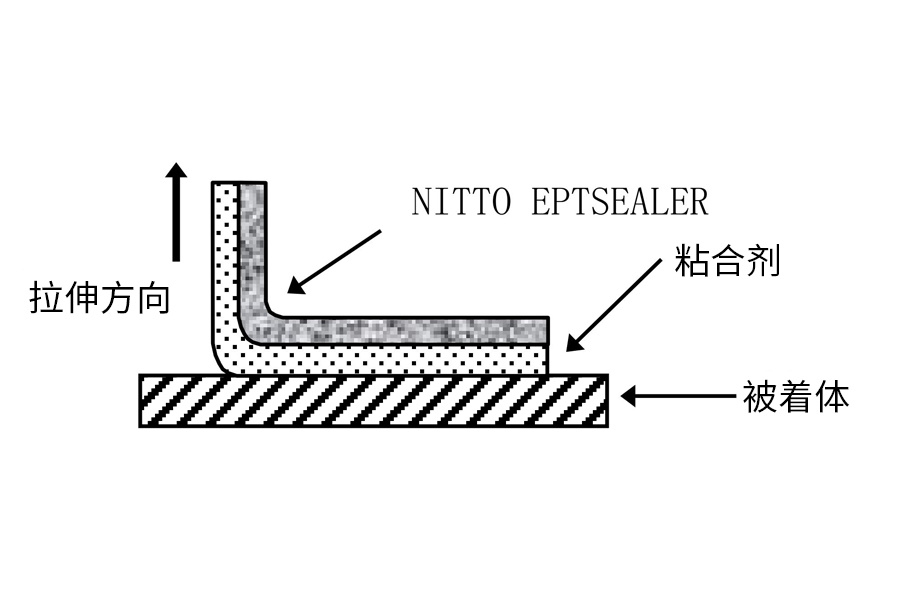

●Adhesive force (90 ° peel off)

|

NITTO EPTSEALER |

NO.681 |

NO.6801 |

NO.6801P |

EM-142 |

|

Adhesive force (N/15mm) |

5.7 |

7.2 |

6.8 |

12.0 |

Use a 2kg roller to press and stick the stainless steel plate back and forth once, and leave it for 30 minutes,

Measure the peel adhesion force at a speed of 300mm/min. Measure the temperature at 23 ℃.

Application:

1. Sealing of the adhesive part of the air conditioning chassis

2. Parts that require high waterproof performance

3. Installation part of sunroof

Previous page

Page top