Product Center

retail price

Market price

weight

kg

inventory

Hidden domain element occupancy

Category:

Sticky Tape

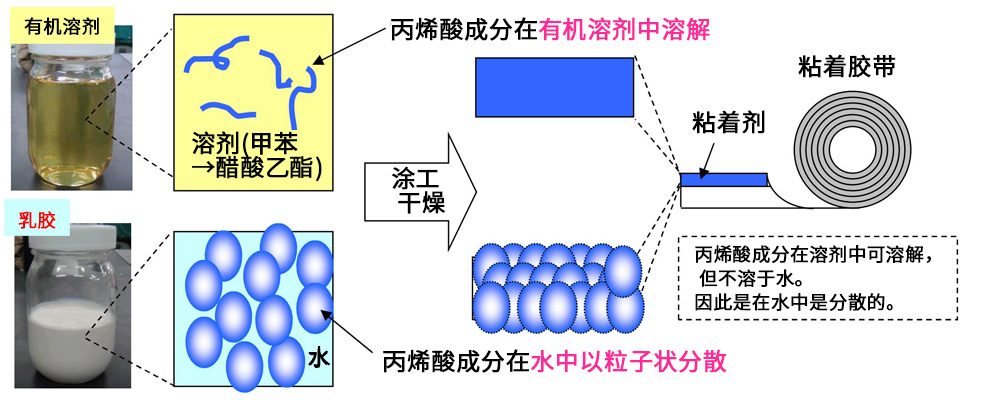

(Nitto) solvent-free technology ①

If organic solvents are used, there may be trace amounts of solvent remaining in the tape, which may produce unpleasant and harmful odors after volatilization. Nitto's low VOC double-sided tape does not experience the above situation due to the use of latex adhesive.

Latex (Em) adhesive

Nitto's solvent-free technology ②

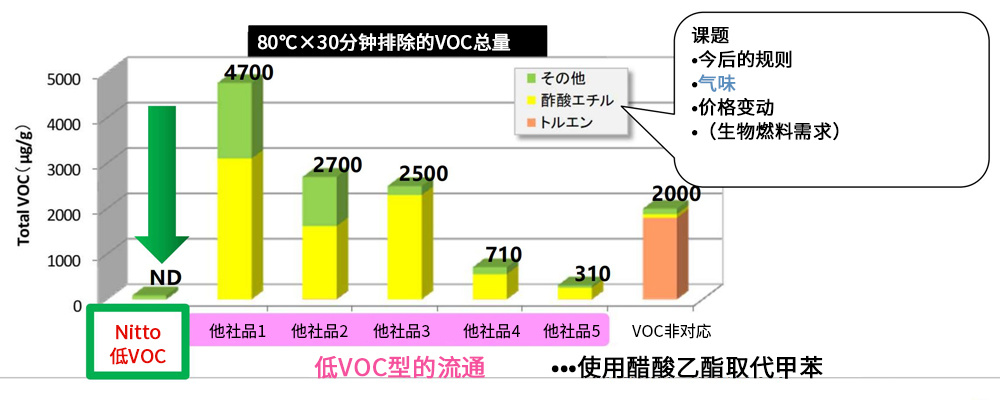

The low VOC double-sided tape we refer to refers not only to products that do not contain regular substances, but also to tapes with a low total VOC content

VOC emissions of low VOC double-sided tape

Due to the use of latex adhesive, not only is there no toluene, but the total emissions of VOCs are also very low.

Technical Data Sheet::

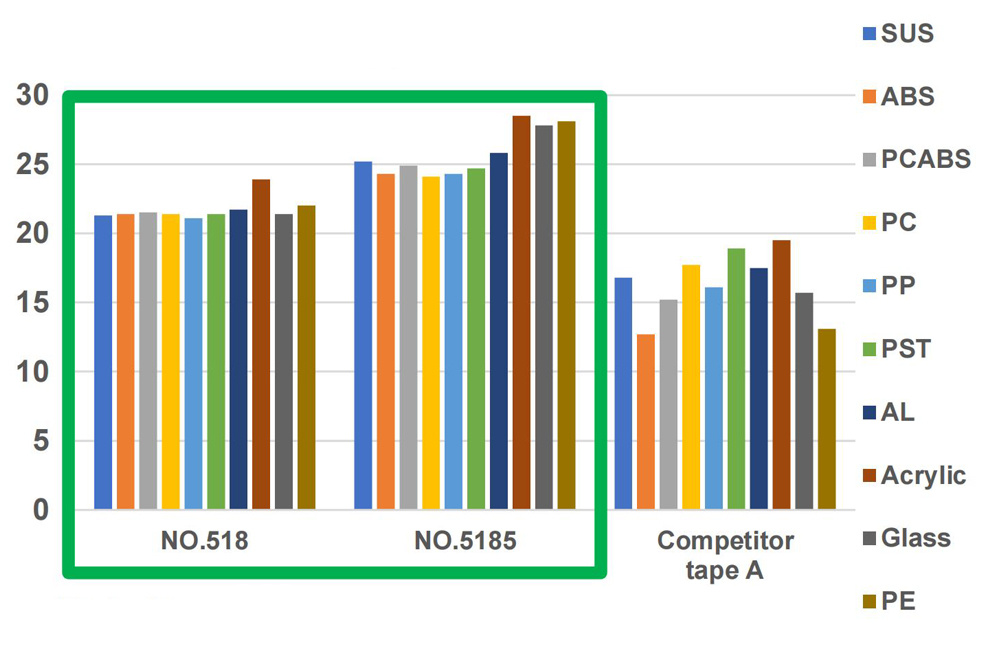

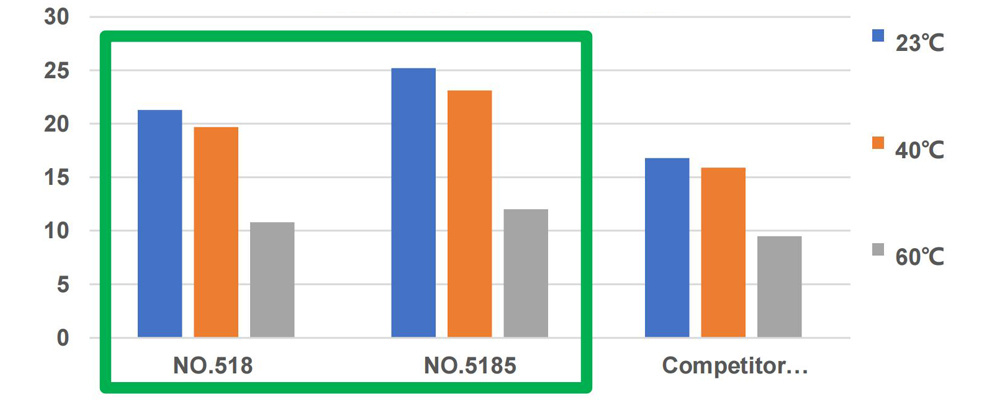

Performance Comparison Report of NO.518 Double sided Adhesive Tape. And a comparative report between NO.5185 and competitors

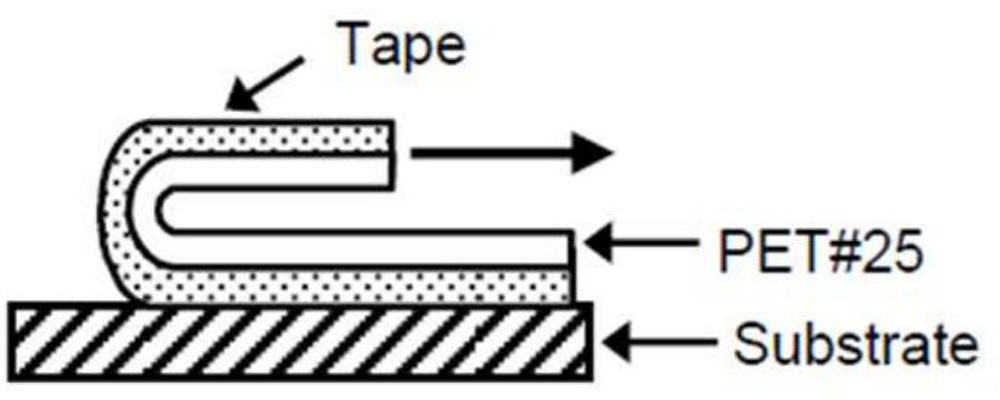

Tape structure

|

Items |

NO.518 |

NO.5185 |

Competitors |

|

Structure |

|

|

|

|

An adhesive |

Acrylic adhesive (Non soluble type) |

Acrylic adhesive (Non soluble type) |

Acrylic adhesive (Non soluble type) |

|

Thickness (mm) |

0.1mm |

0.145mm |

0.15mm |

|

Adhesive force (N/20mm) |

21.3 |

25.2 |

16.8 |

|

Tape color |

Colorless |

Colorless |

Colorless |

The above thickness is measured using a digital measuring instrument. The above values are measured and not guaranteed. The product is currently in the development stage, so this design may undergo changes

Technical data sheet:

180 degree peeling force

|

Substrate |

NO.518 |

NO.5185 |

Competitors |

|

SUS (stainless steel plate) |

21.3 |

25.2 |

16.8 |

|

ABS (Plastic) |

21.4 |

24.3 |

12.7 |

|

PCABS ((Plastic) |

21.5 |

24.9 |

15.2 |

|

PC((Plastic) |

21.4 |

24.1 |

17.7 |

|

PP((Plastic) |

21.1 |

24.3 |

16.1 |

|

Pst(Polystyrene plastic) |

21.4 |

24.7 |

18.9 |

|

AL(Aluminum plate) |

21.7 |

25.8 |

17.5 |

|

Acrylic plate |

23.9 |

28.5 |

19.5 |

|

Glass |

21.4 |

27.8 |

15.7 |

|

PE (Plastics) |

22 |

28.1 |

13.1 |

The above thickness is measured using a digital measuring instrument

The above are measured values, not guaranteed values.

The product is currently in the development stage, so this design may undergo changes

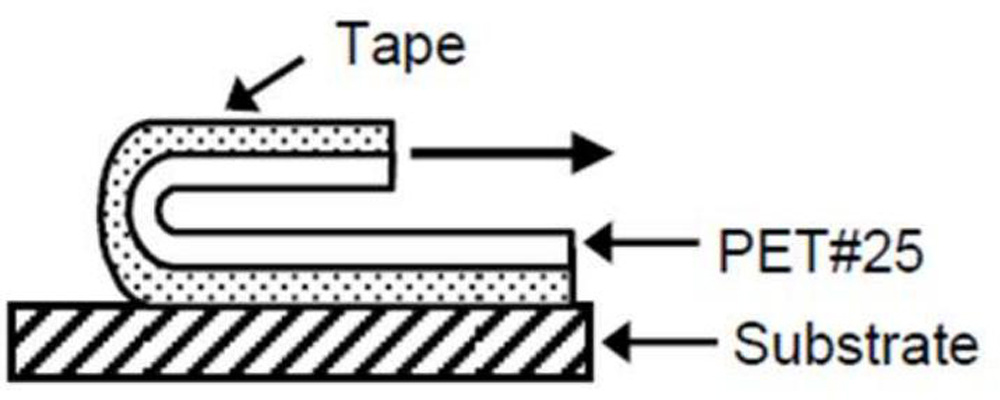

Adhesive strength on different substrates

Evaluation method: (Unit: N/20mm)

Backing material: PET#25

Condition: 23degreeC/50%RH

Lamination:2kg roller x 1 pass back

Aging time: 30 min

Peeling angle: 180degree

Peeling speed: 300 mm/min

Technical Data Sheet:

180 degree peel adhesion of SUS at different temperatures

|

Temperature |

NO.518 |

NO.5185 |

Competitors |

|

23℃ |

21.3 |

25.2 |

16.8 |

|

40℃ |

19.7 |

23.1 |

15.9 |

|

60℃ |

10.8 |

12 |

9.5 |

Evaluation method: (Unit: N/20mm)

Backing material: PET#25

Substrate: SUS

Condition: 23degreeC/50%RH

Lamination:2 kg roller x 1 pass back

Aging time: 30 min

The above thickness is measured using a digital measuring instrument and is a measured value, not a guaranteed value. The product is currently in the development stage, so this design may undergo changes

Adhesive strength of SUS at different temperatures

Technical Data Sheet::

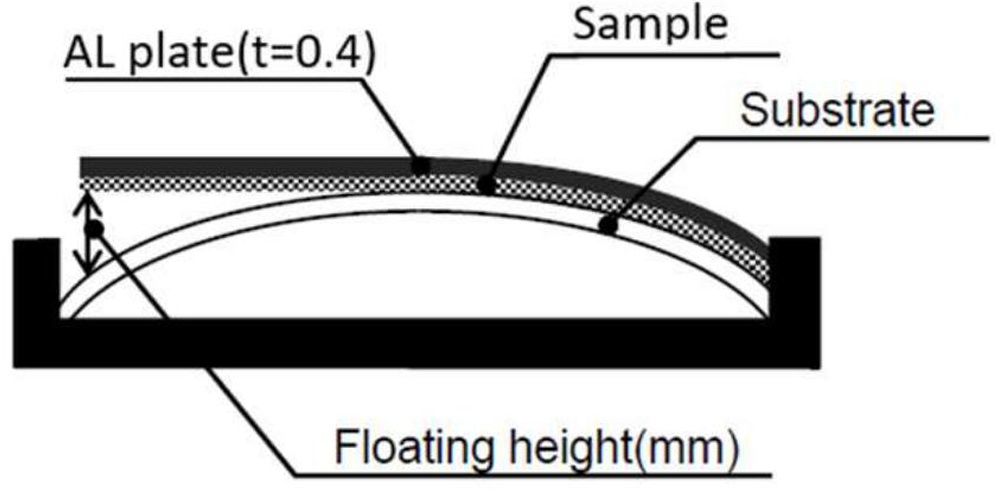

For the anti stripping force of each plastic board

|

Substrate |

NO.518 |

NO.5185 |

Competitors |

|

ABS |

1 |

1 |

Tilting |

|

PP |

1 |

1 |

Tilting |

|

Pst |

1 |

2 |

Tilting |

(Unit: mm/72Hr)

AL plate: 20mm x 180mm

Substrate size: 30mm x 200mm

Repulsion condition: Laminate a substrate and AL plate with tape by laminating machine.

Fit the left sample into wooden mold then leave it at 70 degree C x 72 Hrs and measure

the floating height.

The above thickness is measured using a digital measuring instrument

The above are measured values, not guaranteed values.

The product is currently in the development stage, so this design may undergo changes

Application:

TV, Switch nameplates and decorative sheets for laptops around KYEBORD, household appliances (air conditioners) (toilets), and insulation materials for refrigerators.